EWI: Tackling the Skilled Labor Shortage With Smart Manufacturing

Leveraging Real-Time Streaming to Facilitate Tele-Welding From Anywhere

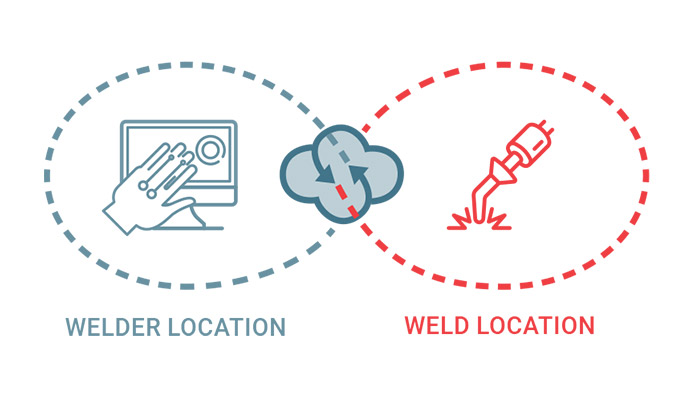

EWI created a system that combines live streaming with robotics for remote welding operations. Dubbed tele-welding, this technology enables welders to flexibly complete their jobs from a distance — while staying safe from hazardous conditions. Implementation of the system will allow manufacturers to retain skilled welders who can no longer operate in the field or be physically at the welding site

400,000+

welding positions are projected to be in a deficit of U.S. workers by 2024.1

$384.4 billion

is the projected value of the smart manufacturing market by 2025.2

<500 ms

latency was achieved by relying on Wowza’s engineers for configuration.

Case Study Snapshot

| Challenges: | Solutions: | Outcomes: |

|

|

|

Bringing Telecommuting to the Manufacturing Sector

If anyone doubted it before the pandemic, it’s an accepted truth today: getting work done remotely is the new normal. CEOs now conduct quarterly all-hands calls from the comfort of their living rooms, whereas doctors monitor and treat patients via video streaming technologies.

Many historically blue-collar positions have been slower to adapt. So, with the major shortage of skilled tradespeople in the welding industry, EWI set out to advance manufacturing technology by building a tele-welding solution.

“Manual welding is often done under dark, dirty, and sometimes dangerous conditions,” explains Connie LaMorte, principal engineer at EWI. “Robots and automation have the ability to reach awkward or unsafe places and perform repetitive welds. However, a human welder’s intellect and skillset are required to ensure the operation is producing an acceptable weld, especially for critical welds on structures or on expensive components.”

Delivering Remote Welding Environments to Welders’ Desktops

To bring this idea to life, EWI teamed up with Wowza Media Systems. But developing a solution that would enable experienced welders to remotely operate equipment required several key capabilities.

For one, the live stream needed to deliver high-quality video and audio data anywhere in the world — thus giving remote operators full access into visual and audio cues. From there, low-latency technologies were critical to supporting a truly interactive experience.

LaMorte and her team decided to leverage Wowza Streaming Engine as their streaming server software and also partnered with our in-house engineers for strategic guidance and custom implementation.

“When welding, the two most important senses a manual operator uses are watching the welding puddle and listening to the arc,” says LaMorte. “To facilitate remotely operated welding, we needed an audiovisual live stream to be transmitted to a welder who could be anywhere from 20 feet to over 500 miles away from the welding process. More importantly, low latency was critical to our application because the welding process occurs in real time.”

Accelerating Digital Transformation During COVID-19 and Beyond

EWI teamed up with Wowza to ensure that these capabilities formed the backbone of their solution. By architecting a workflow to deliver WebRTC streams from end to end, they were able to achieve both their latency and quality needs. Even without extensive streaming expertise in-house, enlisting the help of Wowza Professional Services made it easy.

“Wowza helped initially by walking us through the different options and process of what was needed,” LaMorte says. “The Professional Services team took the time to make sure they understood our application and guided us to the best solution.”

Thanks to EWI, there is now a prototype tele-welding system that can improve employee safety, extend the career length of the professional welding workforce, increase worker retention, and enable more advanced capabilities that improve productivity. The EWI tele-welding solution supports less than 500 millisecond delivery time between the welding site and welder’s location — with smooth video and audio streaming to boot.

Although EWI first set out to develop their tele-welding solution in 2019, the COVID-19 pandemic expedited the need for flexible solutions in manufacturing. Cameras, sensors, and robotics connected to internet of things (IoT)-enabled ecosystems will shape manufacturing processes of the future. And today, EWI is a driving force behind this industry-wide digital transformation.

Sources: